|

SICHUAN GAODETE TECHNOLOGY CO., LTD

|

Gold Index: 8215

You are here: home > Liner barrel surface, Ball mill liners, Magnetic Lining

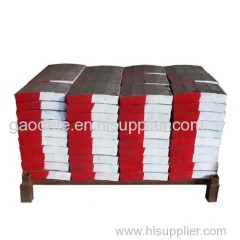

Liner barrel surface, Ball mill liners, Magnetic Lining

| Price: | 915.0~916.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Sichuan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Production Capacity:

480

Product Type:

Others

Brand Name:

gaodete

Hcj(Oe):

2900

BR(Gs):

4200

Delivery Date:

1 week

Machine Type:

Mill

Material:

Non-magnetic alloy steel

(BH)max:

4.0

Improve the mill operation efficiency, power saving, Long life cycle, wear-resisting, light weight and thin thickness, small noise, easy installation,

Ⅰ, Our technical support:

Sichuan Gaodete Technology Co., Ltd. unite domestic top experts in magnetic materials jointly developed the third generation of rare earth metal composite magnetic lining board (Grinding media smaller than 80mm, Sec Ball mill) and the fourth generation Nano toughened metal composite magnetic liner (for grinding media less than 100mm, A ball mill).

My company's fourth-generation Nano toughened metal composite magnetic liner had been used in early 2009 with success in MQG3660 ball mill, equipment operation four years and found no obvious signs of wear, no significant attenuation of the magnetic field.

Ⅱ, Working principle:

When a non-uniform permanent magnetic metal magnetic liner is mounted in a ball mill, using its own permanent magnetic liner, One side firmly adsorbed on the cylinder and the end cap, the other side tightly adsorbed with ball mill crushed and small ferromagnetic media, forming a protective layer adsorption. When the protective layer reaches a certain thickness, the liner with grinding media in movement and the material is no longer have a direct impact and abrasion, thereby reducing the wear rate of the liner, the period of use of liner greatly extended. The protective layer is always in dynamic equilibrium of worn and the added, played the role of magnetic liner permanent protection. Magnetic Lining life can reach several times of the normal manganese steel liner.

Ⅲ, Component:

Metal magnetic liner is composed of three parts: a metal body (housing), the permanent magnet (magnet cover polyaddition) and the elastic layer. Magnetic circuit design using a ball mill cylinder liner, cover the circumferential direction within a N-S poles are alternately arranged, is an open magnetic system.

Related Search

Ball Mill

Spherical Surface Ball Bearing

Magnetic Ball

Large Ball Mill

Steel Ball Mill

Ball End Mill

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

SICHUAN GAODETE TECHNOLOGY CO., LTD [China (Mainland)]

Business Type:Manufacturer, Trading Company, Distributor/Wholesaler

City: Chengdu

Province/State: Sichuan

Country/Region: China (Mainland)

.gif)