|

SICHUAN GAODETE TECHNOLOGY CO., LTD

|

Gold Index: 8215

You are here: home > Quality liner(Barrel surface), Quality magnetic liner(Barrel surface)

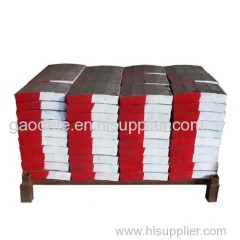

Quality liner(Barrel surface), Quality magnetic liner(Barrel surface)

| Price: | 915.0~916.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Sichuan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Production Capacity:

480 square meters/month

Machine Type:

Others

Material:

Non-magnetic alloy steel

(BH)max:

4.0

Product Type:

Others

Brand Name:

gaodete

Hcj(Oe):

2900

BR(Gs):

4200

Improve the mill operation efficiency, power saving, Long life cycle, wear-resisting, light weight and thin thickness, small noise, easy installation

The working principle of ball mill magnetic liner:

1, Embedded magnetic material in the alloy castings to form liner;

2, Magnetic liner absorb in the cylinder wall by magnetic;

3, Adsorb broken ball on the liner wall by magnetism, forming a protective layer;

4, Through the protective layer to protect magnetic lining, making it durable.

Performance advantages of magnetic ball mill liner:

Compared with the traditional manganese steel liner, it is long life, light weight, thin thickness, provincial ball, energy saving, low noise, the operating rate, and do not bolt, easy installation, no leakage pulp, good working environment, greatly reducing the labor intensity, less accidents, less spare parts consumption. According to the production practice verification, use magnetic lining board in big ball mill, its life than manganese steel lining board to extend the 4 to 6 times, it has very remarkable comprehensive benefit, is the favorable measures metallurgical mining efficiency and reducing consumption, loved by customers.

1, A magnetic lining life: In iron ore Sec, three sections generally 4-6 years, non-ferrous metal ore Sec, three sections generally 2-4 years

2, This product is light weight, is 40-50% manganese of steel liner. So the ball can reduce power consumption, lower 7-10% manganese than steel liner.

3, This product can not leak ore mill, not grinding bearing, no magnetic agglomeration

4, This product is easy to install, installed the day under normal circumstances, reduce labor intensity

5, the best use of the environment of this product:

(1) medium temperature 0 ℃ - 100 ℃

(2) the use of the ball diameter Ф60mm and below

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

SICHUAN GAODETE TECHNOLOGY CO., LTD [China (Mainland)]

Business Type:Manufacturer, Trading Company, Distributor/Wholesaler

City: Chengdu

Province/State: Sichuan

Country/Region: China (Mainland)

.gif)